7 Types of Brick for Home and DIY Projects

7 Types of Brick for Home and DIY Projects

Brick is arguably the most durable building material. If well maintained, brick walls, foundations, pillars, and patios can last decades, even centuries.

While classic red bricks are found on many homes and buildings, brick types are varied and numerous: burnt clay, unburnt clay, handmade, concrete, engineered, fly ash, and more.

Learn the most common types of bricks, their uses, and their limitations.

Brick Sizes and Costs

A brick is a building unit traditionally made of shaped clay and joined with mortar.

Typically, brick sizes are about 8 inches long and 4 inches wide, coming in various thicknesses. Standard brick prices vary widely from $.25 to $4 per brick. Larger stone- or clay-based building units, such as those used in foundations, are called blocks.

In modern construction practices, bricks are categorized according to their component materials and method of manufacture. Under this classification, here are seven common types.

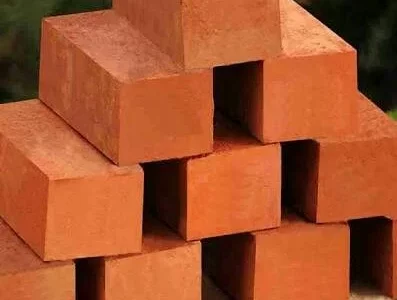

Burnt Clay Bricks

:max_bytes(150000):strip_icc():format(webp)/GettyImages-898234162-359f249e98604806973b37dd1922ce87.jpg)

JessAerons / Getty Images

Burnt clay brick is one of the very oldest building materials found in many of the ancient structures of the world. Classic burnt clay bricks are created by pressing wet clay into molds, then drying and firing them in kilns. In appearance, these bricks are solid blocks of hardened clay and usually reddish.

Burnt clay bricks are typically sold in four classes. First-class burnt-clay bricks are the finest, offering the best quality and strength. These high-grade burnt clay bricks have no noticeable flaws and cost more than lower classes.

When burnt clay bricks are used in walls, they require plastering or rendering with mortar. Uses for burnt clay bricks include masonry walls, foundations, and columns.

Sun-Dried Clay or Mud Bricks

:max_bytes(150000):strip_icc():format(webp)/fired-clay-bricks-sit-on-a-kiln-car-at-a-brickmaking-plant-962948030-5c4f7a7ec9e77c0001f3241d.jpg)

Sun-dried clay bricks, also known as mud bricks, are one of the oldest styles of bricks, but also the least durable.

Sun-dried bricks are made by putting mud into a form and baking them in the sun. When the loaves of mud are dry, they are stacked and held together with more mud. Classic adobe-style homes are made with extremely thick walls constructed of mud brick.

Sand Lime Bricks

:max_bytes(150000):strip_icc():format(webp)/GettyImages-510400108-18a0dc1fe8a440caaebc17bdc4747774.jpg)

Sand lime bricks are often used in structural foundations and walls, exposed brick and pillars, and, when the pigment is added, for ornamental uses.

Sand lime bricks (calcium silicate bricks) are made by mixing sand, fly ash, and lime. Pigments may also be added for color. The mixture is then molded under pressure to form bricks. Sand lime bricks offer advantages such as:

- Smoothness

- Strength for bearing loads

- Easily pigmented

- Less mortar required

- Precise edges

Engineering Bricks

:max_bytes(150000):strip_icc():format(webp)/GettyImages-1250432112-9ca4ae90c5374a26adb1ce892c46e365.jpg)

Valeriya Rychkova / Getty Images

Engineering bricks are used when strength and resilience against the elements are essential. They are clay-based and can be mixed with many other materials.

Their extreme durability sets engineering bricks apart from other types. They are fired at extremely high temperatures. They also have very low porosity and are used in places like sewers, retaining walls, manholes, foundational work, and underground tunnels, where resistance to water and frost is crucial.1

Concrete Bricks

:max_bytes(150000):strip_icc():format(webp)/GettyImages-154954628-2bd4e1df58fa406aaa524aa5bf180908.jpg)

ilbusca / Getty Images

Concrete bricks are made from solid concrete poured into molds. They are traditionally used in internal brickwork but are more frequently used in exterior work, such as facades and fences, to provide a modern or urban aesthetic. Concrete bricks can be manufactured in different colors if pigments are added during production.

Due to their durability, concrete bricks can be used in almost any construction except underground since they tend to be porous.2

Fly Ash Clay Bricks

:max_bytes(150000):strip_icc():format(webp)/Fly_Ash_Bricks_crop-7c649a12c8df451b94071c7f27caff8f.jpg)

Fly ash clay bricks are manufactured with clay and fly ash—a byproduct of coal burning—fired at about 1,832 degrees Fahrenheit. This type of brick is sometimes described as self-cementing since it contains a high volume of calcium oxide and expands when exposed to moisture. This tendency to expand, however, can also produce pop-out failure.3 Fly ash clay brick is lighter than clay or concrete brick.

Typical uses for fly ash clay brick include:

- Structural walls

- Foundations

- Pillars

- Anywhere that improved fire resistance is required

Fire Bricks

:max_bytes(150000):strip_icc():format(webp)/GettyImages-1329919756-4c1b46dd23634250be3c6374f0fc45e2.jpg)

A fire brick, or refractory brick, lines places that are in contact with or near direct flames, such as furnaces, kilns, fireplaces, chimneys, barbecues, and pizza ovens.4

Fire bricks are made from a special mixture of silica and a high aluminum oxide content to withstand excessive heat. They are baked in kilns at extremely high temperatures approaching 2912°F.

Benefits of Using Bricks

There are many advantages when bricks are used in construction.

- Aesthetics: A vast selection of colors and textures.

- Strength: High compressive strength and resists wear and tear..5

- Porosity: The ability to release and absorb moisture helps regulate temperatures and humidity inside structures.6

- Fire protection: Protection against fire up to eight hours, for some types of brick.7

- Soundproofing: Sound dampening that can block up to 200 decibels.5

- Insulation: Excellent thermal insulation, saving up to 50-percent more energy than wood.6

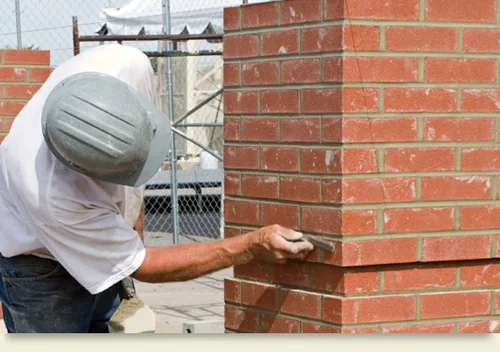

How Bricks Are Made

Bricks are made in various ways, often from a clay-based material, molded into shape, and then fixed in form with heat or other drying processes.

The oldest bricks used natural clay and were dried in the sun. Sun-dried bricks may be the oldest type but also the weakest. Over time, techniques were developed to make bricks stronger and more resilient to weight, heat, weather, and erosion.

The composition of bricks can be changed to achieve desired qualities by mixing clay with concrete, ash, or various chemicals for different purposes. For example, fire bricks contain silica and alumina so they can remain extremely durable when exposed to direct flames.

How Bricks Are Categorized

Brick can be categorized in several ways. For example, you can divide brick in the following three ways:

- By facing: Facing (exposed) vs. backing (structural and hidden from view)

- By manufacturing method: Unfired (air-cured) vs. fired (oven-baked)

- By use: Common bricks (used for residential construction) vs. engineering bricks (used in heftier civil projects)